Introduction

In today’s fast-paced industrial world, efficiency and reliability are critical. Among the many components that keep systems running smoothly, the pneumatic quick release coupling plays a surprisingly vital role. These couplings make it possible to rapidly connect or disconnect compressed air lines without tools, saving time and minimizing downtime. From manufacturing floors to electronics assembly plants, pneumatic couplings ensure that equipment powered by compressed air operates seamlessly, safely, and with maximum productivity.

What Is a Pneumatic Quick Release Coupling?

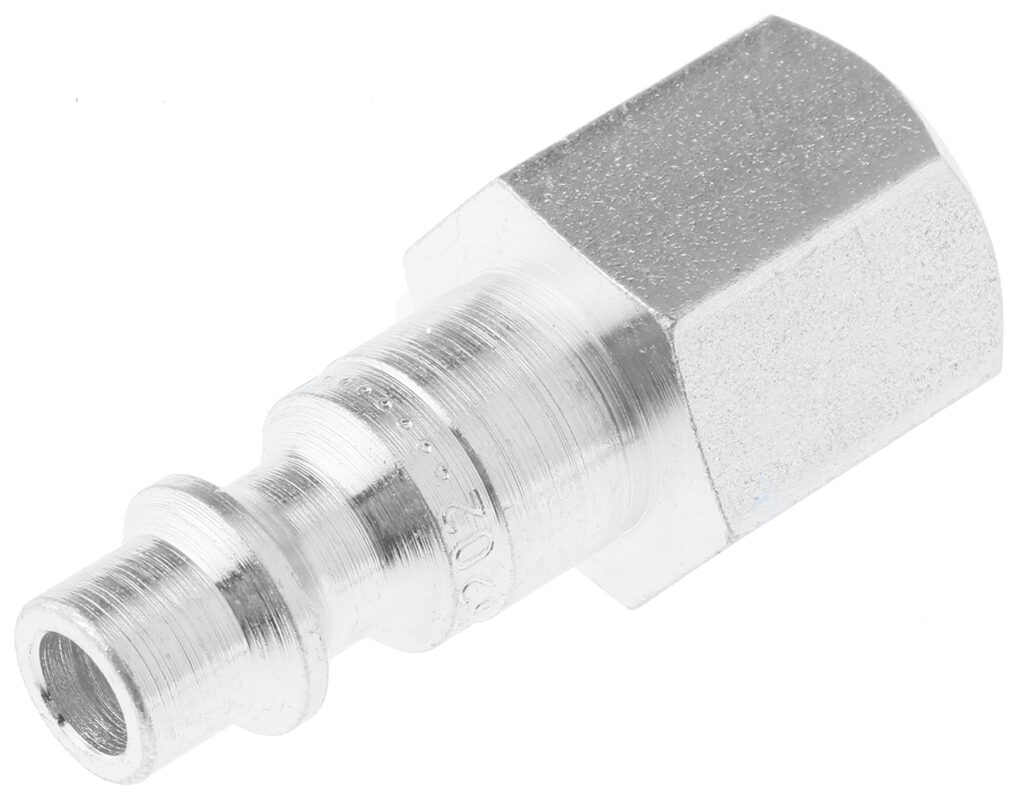

A pneumatic quick release coupling is a device designed to connect an air supply line to a pneumatic tool, actuator, or machine. Unlike threaded fittings, which require wrenches and take time to secure, quick release couplings use a push-and-lock or click mechanism. This design ensures a tight seal, preventing leaks and maintaining consistent air pressure.

Couplings are available in various international standards—such as Industrial Interchange, British, and Japanese types—making them suitable for regional requirements. The adaptability of these connectors ensures that users can switch between tools or replace lines without interrupting workflows.

Applications Across Industries

The versatility of pneumatic quick release couplings makes them indispensable across multiple sectors:

- Electronics Manufacturing – Powering soldering systems, PCB cleaning, and robotic placement tools.

- Automotive Workshops – Allowing mechanics to shift quickly between impact wrenches, spray guns, and blowers.

- Medical Equipment – Supporting precision air-driven tools in clean and hygienic environments.

- Food and Beverage – Delivering compressed air safely in packaging and bottling machines.

- Construction – Powering nail guns, drills, and other pneumatic devices on job sites.

In each case, the ability to connect and disconnect air tools effortlessly reduces downtime and increases productivity.

Benefits of Pneumatic Quick Release Couplings

- Time Efficiency – Instant connections save valuable work hours.

- Energy Conservation – Secure seals reduce compressed air leaks.

- Enhanced Safety – Many designs feature automatic shut-off valves to prevent accidents.

- Durability – Built to withstand vibration, oils, and thermal fluctuations.

- Versatility – Compatible with a wide range of tools and compressed air systems.

Pneumatics Meets Electronics

While pneumatic systems provide mechanical power, electronics bring precision and control. In modern factories, sensors, microcontrollers, and controllers regulate the performance of pneumatic tools. For example, in automated assembly lines, a pneumatic actuator may be controlled by an electronic PLC (Programmable Logic Controller) that sends exact commands to start or stop motion.

Quick release couplings make this integration seamless by enabling fast reconfiguration of tools or actuators without affecting electronic programming. They act as a physical interface between mechanical air systems and electronic intelligence, ensuring flexibility and accuracy in production environments.

Materials and Designs

Pneumatic quick release couplings are available in a variety of materials, each suited to specific environments:

- Brass – Resistant to corrosion and oils, ideal for general workshops.

- Stainless Steel – Hygienic and durable, preferred in food, medical, and cleanroom applications.

- Composite/Plastic – Lightweight and cost-effective for lighter-duty electronic and mechanical tasks.

Design options include single shut-off and double shut-off types. The latter prevents both ends of the line from leaking air when disconnected, crucial in sensitive areas like electronics production where stability is key.

Role in Power and Energy Systems

Pneumatic quick release couplings also support energy-efficient air systems. By minimizing leakage and ensuring consistent pressure, they reduce the load on compressors, saving electricity. In renewable energy facilities, pneumatic systems sometimes integrate with electronic controllers, capacitors, and sensors for tasks such as valve actuation or component alignment. Reliable couplings ensure these operations run smoothly without air loss.

Choosing the Right Coupling

Selecting the right pneumatic quick release coupling depends on:

- Airflow Requirements – Matching the coupling’s capacity to the tool’s demand.

- Pressure Rating – Ensuring the coupling handles the system’s maximum operating pressure.

- Operating Environment – Considering exposure to dust, oils, or thermal changes.

- Compatibility – Verifying the profile standard with existing fittings and connectors.

Suppliers like Enrgtech offer a broad selection of high-quality, certified couplings that meet international standards, helping businesses maintain efficiency and safety across diverse applications.

Future of Pneumatic Quick Release Couplings

As industries embrace automation and smart manufacturing, pneumatic couplings are evolving. Many are now being equipped with IoT-enabled sensors that provide real-time data on airflow, leakage, and thermal variations. By combining mechanics with electronics, industries can adopt predictive maintenance strategies, reducing unexpected downtime.

Sustainability is another major trend. Manufacturers are developing eco-friendly couplings with energy-efficient seals and recyclable materials, aligning with global goals for reduced environmental impact.

Conclusion

The pneumatic quick release coupling may be a small component, but its impact is enormous across industries that depend on compressed air. By enabling fast connections, reducing leaks, and integrating seamlessly with electronic control systems, these couplings ensure efficiency, safety, and reliability.

From electronics assembly and robotics to automotive workshops and renewable energy systems, pneumatic couplings remain central to innovation and productivity. Sourcing through trusted distributors like Enrgtech ensures businesses gain access to authentic, certified products that deliver long-term performance. In an era of automation and digital transformation, pneumatic quick release couplings will continue to play a vital role in keeping industries powered, precise, and productive.