Terminal blocks serve as pivotal components in electrical and electronic circuit systems. When it comes to efficient wiring, ease of use, and a secure connection, DIN Rail Terminal Blocks are among the top choices for many professionals. To understand their significance, let’s delve into what they are and explore the types available.

Understanding DIN Rails and Terminal Blocks

Before diving into the heart of the matter, it’s crucial to understand what a DIN Rail and a Terminal Block is individually.

- DIN Rails: The term ‘DIN’ stands for ‘Deutsches Institut für Normung,’ which is the German institute for standardization. DIN Rails are metal railings, usually made of steel or aluminum, standardized to specific dimensions, mainly used for mounting circuit breakers and industrial control equipment inside equipment racks.

- Terminal Blocks: These are modular, insulated devices that secure two or more wires together. They act as a convenient point where the wires can be either connected or disconnected.

Merging these two concepts gives us the DIN Rail Terminal Block – a terminal block designed to be easily mounted or snapped onto a DIN Rail.

Types of DIN Rail Terminal Blocks

With technology’s progress, the diversity in DIN Rail Terminal Blocks has grown. They cater to various applications and requirements. Here are the most common types:

Screw Terminal Blocks:

- Description: These are the traditional types where the wire connections are secured with screws. The wire is inserted into the terminal, and a screw is tightened to secure the connection.

- Applications: Widely used in various sectors, from residential to industrial applications. Their robust nature and reliable connection make them popular.

Spring Clamp Terminal Blocks:

- Description: As the name suggests, these terminal blocks use a spring mechanism. When the wire is inserted, the spring holds it securely, eliminating the need for screws.

- Applications: These are suitable for applications where vibration is a concern. The absence of screws means the connection is less likely to become loose over time.

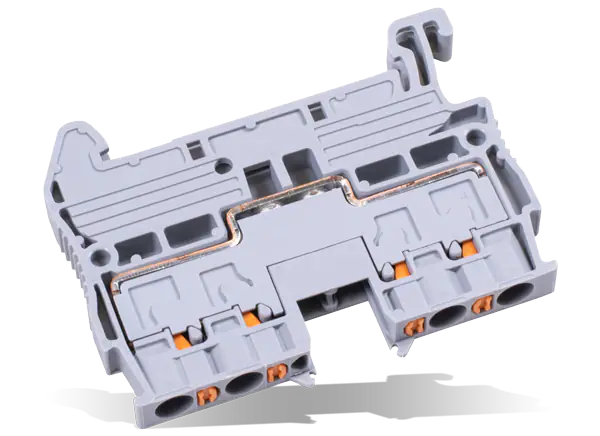

Push-in Terminal Blocks:

- Description: Push-in technology allows for direct insertion of a wire into the terminal block without the need for any tools. This ensures a secure and quick connection.

- Applications: Mostly preferred for applications that demand rapid wiring or frequent wire modifications.

Barrier Terminal Blocks:

- Description: These blocks come with a barrier between each terminal, which ensures that accidental shorting does not occur. They often use screws to secure wire connections.

- Applications: Used in applications that have a higher voltage, ensuring safety against short circuits.

Sectional or Modular Terminal Blocks:

- Description: These terminal blocks are versatile, allowing users to create a terminal block strip of any length. They come with separate sections which can be snapped together.

- Applications: Ideal for custom applications where a specific number of terminals are required.

Pluggable Terminal Blocks:

- Description: These terminal blocks allow for the quick disconnect of wired sections. They consist of a plug section and a mating socket; the socket gets mounted on the board, and the plug is connected to the wires.

- Applications: Beneficial for applications where quick and frequent disconnection is necessary or where sections of the system need to be replaced or serviced without disturbing the entire wiring setup.

Power Distribution

- Description: These are designed to distribute power from a single source to multiple outputs. They’re larger in size and designed to handle higher currents.

- Applications: Used in applications where power distribution to several devices or sections is required.

Benefits of Using DIN Rail Terminal Blocks

- Versatility: The variety of types means there’s a DIN Rail Terminal Block for almost any application.

- Ease of Installation: Their design allows for easy snapping onto the DIN Rail, simplifying installation and modifications.

- Space-saving: The rail mounting system ensures a neat and compact setup, saving valuable space in control cabinets or panels.

- Safety: Their design adheres to international standards, ensuring the safety of the connections.

- Flexibility: Especially with modular blocks, creating a custom solution for specific needs becomes feasible.

Conclusion

In conclusion, DIN Rail Terminal Blocks have revolutionized the way connections are made in electrical setups. Their efficiency, coupled with the variety available, makes them an excellent choice for professionals aiming for a secure, neat, and adaptable connection system. As technology evolves and demands grow, we can expect even more innovations and versatility in DIN Rail Terminal Block designs.