Introduction

When it comes to electrical connections, the importance of reliability, safety, and ease of installation cannot be overstated. Whether you’re working on a residential wiring project or an industrial electrical system, the connectors you use play a pivotal role in ensuring the system operates smoothly. Among the wide range of connectors available, waterproof push-in wire connectors have become an increasingly popular choice due to their durability, security, and resistance to environmental factors. In this blog, we’ll explore the benefits of electrical push-in wire connectors, the different types of push-in wire connectors, and why waterproof variants are essential for ensuring secure connections in challenging environments.

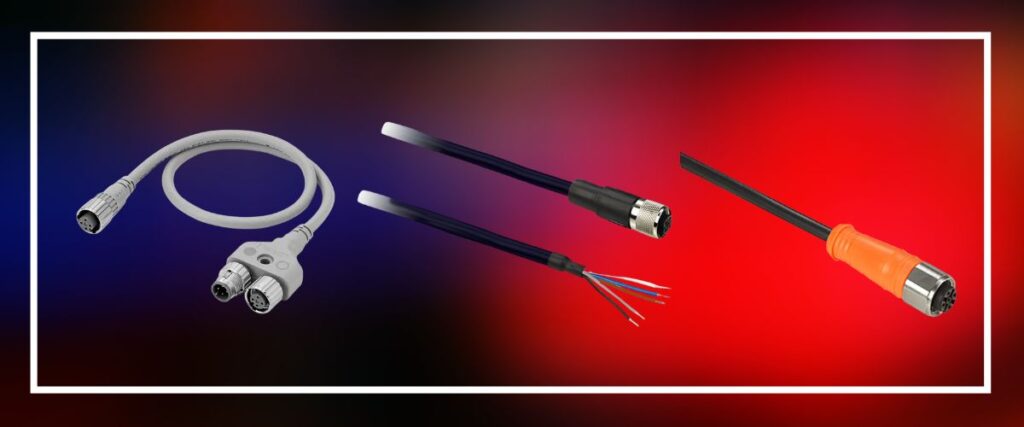

What Are Push-In Wire Connectors?

Push-in wire connectors are a type of electrical connector designed to allow wires to be inserted into terminals without the need for specialized tools or crimping. These connectors offer a quick and secure connection by simply pushing the wire into the connector’s terminal, which locks it in place through an internal spring mechanism. The push-in design not only makes installation faster but also ensures a reliable electrical connection that is both safe and durable.

Whether you’re working with solid or stranded wire, push-in connectors offer a versatile solution that eliminates the hassle of screw tightening, reducing the potential for faulty connections and making them an ideal option for both professional and DIY projects.

Waterproof Push-In Wire Connectors: Key Features and Benefits

Waterproof push-in wire connectors are designed specifically for environments where moisture or water exposure is a concern. These connectors offer an extra layer of protection, ensuring that electrical systems remain intact and functional, even in wet or humid conditions. Let’s take a look at why waterproof push-in wire connectors are essential:

1. Protection from Water Damage

One of the biggest challenges in outdoor or industrial environments is the exposure of electrical systems to water, rain, or moisture. If left unprotected, water can cause corrosion, short circuits, and even electrical fires. Waterproof push-in wire connectors are engineered to prevent water from entering the connection points, offering superior protection against these hazards. They are ideal for use in marine applications, outdoor lighting, irrigation systems, or anywhere electrical systems are exposed to harsh weather conditions.

2. Durability and Longevity

Waterproof push-in wire connectors are built to withstand extreme environmental factors. Their construction typically includes materials such as rubber gaskets or silicone seals that provide an airtight seal around the wire connection. This makes them durable and long-lasting, even in tough conditions, ensuring that the connectors maintain their integrity over time and don’t degrade due to exposure to water or other environmental factors.

3. Easy Installation in Wet Conditions

One of the greatest advantages of push-in wire connectors, including waterproof variants, is their tool-free installation. In environments where access to tools may be limited or inconvenient, push-in wire connectors allow for quick and easy connections. The wire simply needs to be pushed into the connector, making them the ideal choice for installations in wet conditions or areas where time is of the essence.

Electrical Push-In Wire Connectors: Applications and Advantages

Electrical push-in wire connectors come in a variety of shapes, sizes, and configurations to suit different wiring applications. They offer several key advantages over traditional screw terminal or crimp connectors:

1. Speed and Convenience

Electrical push-in wire connectors significantly speed up the installation process. Unlike screw terminals, which require tightening with a screwdriver, push-in connectors simply require the user to push the wire into the terminal. This makes them ideal for large-scale installations, reducing the time spent on wiring while maintaining a secure and reliable connection.

2. Secure and Reliable Connections

The spring mechanism inside the connector ensures that the wire remains securely locked in place, preventing accidental disconnections or wire slippage. This feature is particularly beneficial in environments where vibrations or movement could potentially loosen traditional connectors. Whether you’re working in machinery, appliances, or electrical systems, electrical push-in wire connectors offer a consistent and dependable connection that won’t fail under normal operating conditions.

3. Versatility

Electrical push-in wire connectors are highly versatile and can be used for both solid and stranded wires, making them ideal for a variety of applications. From small DIY electrical projects to larger commercial installations, these connectors provide a flexible solution for different wire gauges and types. Additionally, push-in wire connectors are available in multiple configurations, such as single-port, multi-port, and inline connectors, allowing for customized solutions based on your project’s needs.

4. Space-Saving Design

The compact design of push-in wire connectors makes them a great choice for tight spaces. With traditional screw terminals, you may need additional room for tools, screws, and extra wiring. Push-in connectors, on the other hand, take up less space and offer a cleaner, more organized solution to electrical connections, making them ideal for confined areas such as electrical panels or junction boxes.

Different Ports of Push-In Wire Connectors

There are several types of push-in wire connectors, each designed for different wiring configurations and electrical requirements. The “port” refers to the number of terminals within the connector that can accept individual wires. Here’s a breakdown of the different ports of push-in wire connectors:

1. Single-Port Push-In Connectors

Single-port connectors are the simplest form of push-in wire connectors. They allow for the connection of one wire at a time, making them ideal for individual circuits. These connectors are commonly used in smaller electrical applications where only a single wire needs to be connected, such as in light fixtures or outlet wiring.

2. Multi-Port Push-In Connectors

Multi-port push-in wire connectors feature multiple ports, enabling the connection of multiple wires in a single unit. These connectors are great for branching out circuits or connecting several wires to a single terminal. Multi-port connectors are commonly used in control panels, junction boxes, and other applications where multiple connections need to be made at once, simplifying the wiring process and improving efficiency.

3. Inline Push-In Connectors

Inline push-in wire connectors are designed to create a connection between two wires, often used for splicing or extending wiring. These connectors are beneficial when you need to extend an existing circuit or connect two separate wires in a straight line. They provide a reliable and secure connection while maintaining a neat and organized wiring layout.

How to Use Waterproof Push-In Wire Connectors

Using waterproof push-in wire connectors is simple and straightforward. Here are the basic steps to ensure a secure connection:

- Strip the Wire: Use a wire stripper to remove approximately 10-12mm of insulation from the end of each wire. Be sure not to strip too much insulation, as this could prevent the connector from making a secure connection.

- Select the Right Connector: Choose a waterproof push-in connector that matches the wire gauge you are working with. The connector should fit snugly around the wire to ensure a solid connection.

- Insert the Wire: Simply push the stripped end of the wire into the connector. The internal spring mechanism will securely hold the wire in place.

- Check the Connection: Gently tug on the wire to ensure it’s securely locked in place. If the wire slips out or feels loose, reinsert it or check the connector for compatibility.

- Seal and Test: In outdoor or wet environments, ensure that the waterproof seal is intact before using the connector. Once installed, test the connection to ensure proper functionality.

Conclusion

Waterproof push-in wire connectors provide an excellent solution for ensuring reliable, secure electrical connections in challenging environments. Their tool-free installation, compact design, and water-resistant properties make them ideal for outdoor, industrial, and high-humidity applications. By providing a quick and reliable method of connecting wires without compromising on safety or performance, push-in wire connectors have become a go-to choice for electricians and DIY enthusiasts alike.

Whether you are working with electrical systems in your home, office, or industrial setup, incorporating electrical push-in wire connectors will simplify your wiring process, enhance safety, and improve the durability of your connections. Choose Enrgtech’s high-quality waterproof push-in wire connectors for your next project, and experience the benefits of secure, long-lasting electrical connections today!