Introduction

In modern electrical and electronic systems, safety, reliability, and efficiency are key priorities. Among the many protective components that safeguard these systems, the circuit breaker stands as one of the most vital. A circuit breaker is an automatic electrical switch designed to protect circuits from damage caused by overloads, short circuits, or faults. It ensures that current flow remains within safe limits, preventing hazards such as electrical fires, equipment failure, and system downtime.

From household wiring to industrial automation systems, circuit breakers are used in nearly every electrical installation. They not only provide protection but also enable controlled power distribution and system maintenance. Understanding how they work, their types, and their importance in modern electronic environments is essential for engineers, electricians, and anyone involved in energy management.

What Is a Circuit Breaker?

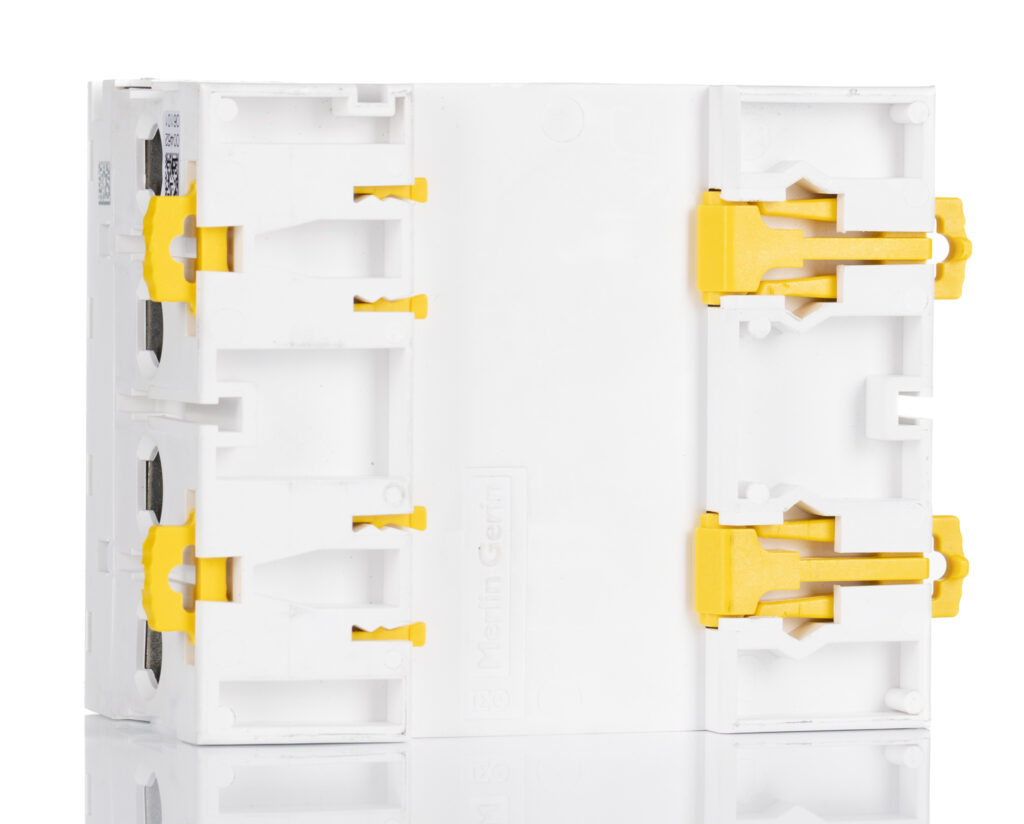

A circuit breaker is a protective device that automatically interrupts the flow of electricity when a fault or overload occurs in an electrical circuit. It functions as a safety mechanism that cuts off power to prevent equipment damage and electrical hazards. Unlike fuses that require replacement after a fault, circuit breakers can be reset manually or automatically, allowing for quick restoration of power.

These devices are designed to handle various current capacities and voltages depending on their application. In residential setups, circuit breakers protect lighting and outlet circuits, while in industrial and commercial systems, they manage high-power electrical machinery, distribution panels, and electronic control systems.

Working Principle of a Circuit Breaker

The fundamental working principle of a circuit breaker is simple: it detects abnormal current flow and interrupts it before damage occurs. Inside the breaker, a contact system carries the electrical current during normal operation. When a fault or overload happens, the excessive current generates heat or magnetic force that triggers a mechanism to separate the contacts, breaking the circuit instantly.

The interruption process occurs in three main stages: detection, disconnection, and arc extinguishing. The arc, which forms when contacts separate, is extinguished using air, oil, vacuum, or gas mediums depending on the breaker type. This ensures that current flow stops safely without damaging the circuit or connected devices.

Types of Circuit Breakers

Circuit breakers are available in multiple configurations, each suited to specific electrical and electronic applications. The most common types include:

Miniature Circuit Breaker (MCB): Used in residential and commercial electrical panels, MCBs provide protection against overcurrent and short circuits. They are compact, reliable, and ideal for low-voltage systems.

Molded Case Circuit Breaker (MCCB): Designed for higher current ratings, MCCBs are used in industrial environments and large-scale electrical networks. They offer adjustable trip settings and are suitable for motors, generators, and heavy machinery.

Residual Current Circuit Breaker (RCCB): Also known as an Earth Leakage Circuit Breaker, RCCBs protect against electric shock by detecting leakage currents caused by insulation failures or faulty wiring.

Air Circuit Breaker (ACB): Commonly used in industrial systems, ACBs are suitable for low to medium voltage applications. They operate using air as the arc extinguishing medium.

Vacuum Circuit Breaker (VCB): These breakers are designed for medium voltage systems. The arc formed during operation is extinguished in a vacuum, ensuring minimal maintenance and long service life.

Oil Circuit Breaker (OCB): Used in high-voltage systems, oil circuit breakers use insulating oil to quench the arc. Though less common today, they were once standard in power distribution networks.

Miniature electronic circuit breakers: Found in automation and control panels, these advanced breakers integrate digital sensors and trip units for precise fault detection and monitoring.

Importance of Circuit Breakers in Electronic Systems

In modern electronics, where precision and reliability are essential, circuit breakers protect sensitive components such as sensors, controllers, and microprocessors. Even minor voltage fluctuations or current surges can cause serious damage in electronic systems. Circuit breakers ensure continuous operation by instantly isolating faulty circuits without affecting the rest of the system.

They also help in maintaining system efficiency by reducing unplanned downtime. In power distribution networks, breakers coordinate with protective relays to isolate only the affected section, keeping the rest of the system operational. In automation and robotics, circuit breakers protect control panels and actuators from faults, ensuring consistent performance and minimizing maintenance costs.

Applications Across Industries

Circuit breakers are widely used across various sectors of the electrical and electronic industries.

- Residential applications: Protect home circuits, appliances, and lighting systems from overloads and short circuits.

- Industrial systems: Safeguard motors, drives, conveyors, and manufacturing equipment from electrical faults.

- Commercial facilities: Manage power distribution in offices, data centers, and hospitals, ensuring uninterrupted operation.

- Renewable energy systems: In solar and wind energy setups, circuit breakers protect inverters, batteries, and converters from electrical faults.

- Telecommunications and electronics: Protect critical circuits in control systems, data transmission lines, and communication equipment.

In every sector, circuit breakers enhance reliability, reduce maintenance costs, and improve safety for both personnel and equipment.

Key Advantages of Using Circuit Breakers

Circuit breakers provide several advantages that make them indispensable in electrical and electronic systems.

- Automatic protection: They detect and disconnect faulty circuits instantly.

- Reusability: Unlike fuses, breakers can be reset after tripping.

- Precision control: Some models include adjustable trip mechanisms for customized protection.

- Long service life: Durable materials and designs ensure years of reliable operation.

- Integration capability: Modern breakers can be integrated into smart monitoring systems and IoT platforms for real-time fault detection.

Technological Advancements in Circuit Breakers

With the rise of automation, smart grids, and industrial electronics, circuit breakers have evolved to include intelligent features. Smart circuit breakers can communicate with energy management systems to provide data on voltage, current, and power usage. They can predict failures, perform self-diagnostics, and even be operated remotely.

Electronic trip units replace traditional thermal and magnetic mechanisms, offering higher accuracy in fault detection. These advancements make modern circuit breakers ideal for smart buildings, renewable energy systems, and automated industrial processes. They improve operational efficiency while reducing the risk of downtime and energy waste.

Safety Standards and Maintenance

Circuit breakers are manufactured according to strict international standards, such as IEC, UL, and ISO certifications. These ensure that breakers meet safety, performance, and reliability requirements. Regular inspection and maintenance are crucial to ensure optimal operation. Dust accumulation, loose connections, and worn-out contacts can reduce performance, so periodic testing helps maintain efficiency.

In high-demand environments, thermal imaging and insulation testing are used to monitor breaker performance and identify potential faults before they escalate. Proper labeling and load balancing across circuits also improve the longevity and reliability of the system.

Conclusion

Circuit breakers form the foundation of electrical safety in both residential and industrial environments. They protect circuits from overloads, short circuits, and ground faults, ensuring the safe and efficient flow of electricity. In electronic systems, they serve as crucial components that preserve the integrity of sensitive devices and prevent costly downtime.

As technology continues to evolve, modern circuit breakers are becoming smarter, more compact, and more energy-efficient. Their integration into digital and automation systems highlights their growing importance in the future of electrical engineering. Whether it’s a home distribution board or a large-scale industrial setup, the circuit breaker remains the ultimate safeguard for modern electrical and electronic systems.