Introduction

The modern industrial world depends heavily on automation for efficiency, reliability, and productivity. At the core of this automation lies a highly versatile device known as the Programmable Logic Controller (PLC). Designed to control machinery, processes, and electronic systems, PLCs are the backbone of manufacturing, assembly lines, and industrial operations. Their ability to handle complex logic, execute instructions quickly, and withstand demanding environments makes them indispensable across industries worldwide.

What is a Programmable Logic Controller?

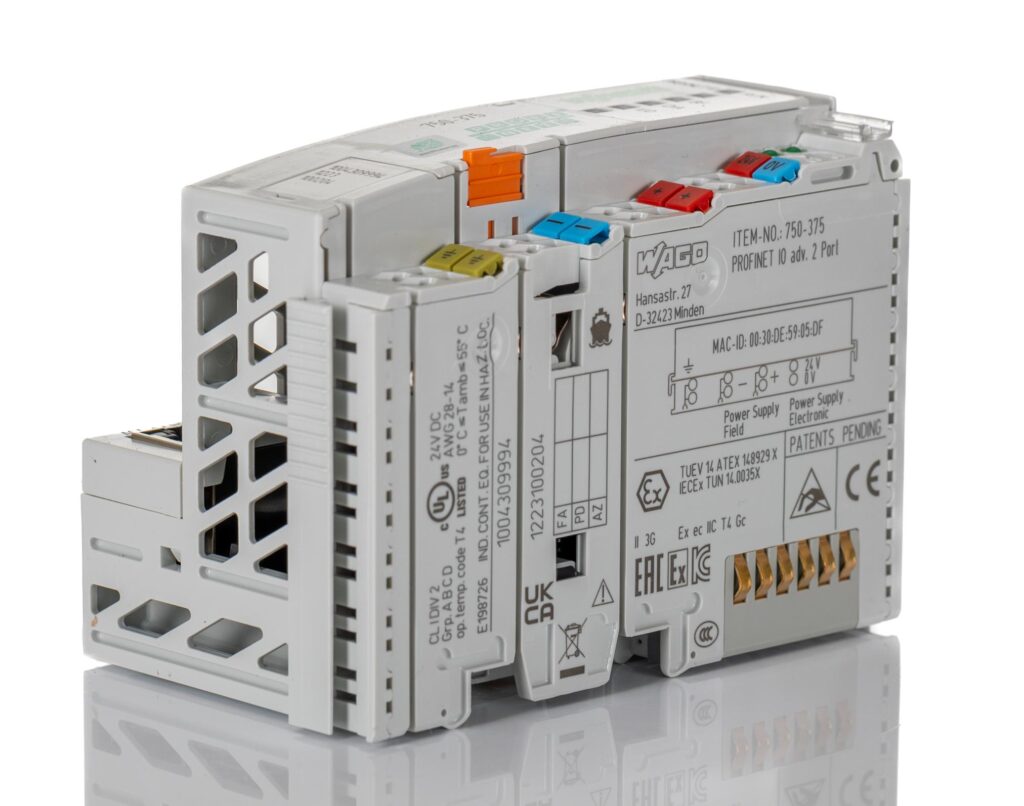

A Programmable Logic Controller is an industrial-grade digital computer designed to manage automated processes. Unlike general-purpose computers, PLCs are specifically built to control electromechanical processes in real time. They are programmed using specialized languages, such as ladder logic, function block diagrams, or structured text, allowing engineers and technicians to design and implement automated systems effectively.

PLCs connect directly with sensors, actuators, and electronic devices, reading input signals, processing them based on logic, and delivering output commands to operate motors, relays, valves, and other equipment.

Key Features of PLCs

PLCs are engineered with features that ensure safe, reliable, and efficient operation in electronics and electrical systems:

- Rugged Design – Built to withstand heat, dust, vibration, and electrical noise.

- Real-Time Processing – Executes control logic instantly for precise automation.

- Modularity – Expandable with additional I/O modules for scalability.

- Communication Support – Compatible with fieldbus networks, Ethernet, and industrial protocols.

- High Reliability – Ensures continuous operation in mission-critical environments.

- User-Friendly Programming – Accessible through ladder logic and other structured programming languages.

These features make PLCs suitable for environments where durability and accuracy are non-negotiable.

Types of Programmable Logic Controllers

PLCs come in different configurations, depending on application requirements:

- Compact PLCs

Integrated units with limited I/O capacity, ideal for small machines and basic automation tasks. - Modular PLCs

Offer scalability with separate modules for power supply, CPU, I/O, and communication. Used in large and complex industrial systems. - Rack-Mount PLCs

Designed for extensive applications, allowing multiple modules on racks for advanced control and communication. - Soft PLCs

Software-based systems running on industrial PCs, blending traditional PLC functions with modern computing.

Applications of Programmable Logic Controllers

PLCs are used across countless industries where automation and precision are essential. Some major applications include:

- Industrial Automation

PLCs control assembly lines, robotic systems, packaging equipment, and conveyor belts in manufacturing plants. - Process Control

In oil, gas, chemical, and water treatment industries, PLCs manage pumps, valves, and sensors for stable process operation. - Building Automation

Lighting, HVAC, and access control systems rely on PLCs for efficient management. - Transportation Systems

PLCs manage railway signaling, escalators, lifts, and airport baggage systems. - Renewable Energy

PLCs regulate turbines, solar arrays, and energy storage systems, ensuring maximum efficiency. - Consumer Goods Industry

From bottling plants to textile machinery, PLCs ensure consistency and productivity in large-scale operations.

Advantages of Using PLCs

PLCs offer numerous benefits that make them vital in electronics and industrial systems:

- Flexibility – Easily reprogrammed to accommodate new processes.

- Cost-Effectiveness – Reduces manual labor and operational downtime.

- Reliability – Designed for continuous operation in harsh environments.

- Precision – Enables accurate control of motors, sensors, and actuators.

- Integration – Works seamlessly with SCADA, HMI, and IoT platforms.

- Scalability – Suitable for small electronic projects and large industrial plants alike.

Technical Considerations for Choosing PLCs

When selecting PLCs, engineers and businesses must evaluate several key factors:

- Input/Output Capacity – Match the number of I/O points with system requirements.

- Processing Speed – Higher speeds ensure smooth operation of complex logic.

- Communication Protocols – Ensure compatibility with fieldbus networks, Ethernet, or IoT devices.

- Environmental Resistance – Consider rugged PLCs for environments with vibration, dust, or extreme temperatures.

- Programming Support – Ensure availability of suitable programming languages and tools.

- Expansion Capability – Choose modular PLCs for scalability in future applications.

Evaluating these factors ensures that PLCs provide maximum efficiency and long-term performance.

Programmable Logic Controllers and Industry 4.0

With the rise of Industry 4.0 and digital transformation, PLCs are evolving into smarter, more connected systems. Modern PLCs support remote monitoring, predictive maintenance, and integration with IoT-enabled devices. They not only control machines but also collect data, optimize processes, and enhance energy efficiency.

For example, in a smart factory, PLCs communicate with sensors and cloud platforms, providing insights that help reduce downtime, improve productivity, and support sustainability goals. This shift makes PLCs an essential part of connected and intelligent manufacturing systems.

Why Choose Enrgtech for Programmable Logic Controllers?

Enrgtech offers a diverse selection of programmable logic controllers from trusted global manufacturers. Every PLC is sourced with certifications to guarantee authenticity, performance, and compliance with international standards.

When sourcing PLCs from Enrgtech, customers benefit from:

- Certified Products with guaranteed reliability.

- Competitive Pricing to support cost-effective automation projects.

- Fast Global Delivery to keep operations on schedule.

- Expert Guidance for product selection and technical support.

With Enrgtech’s trusted portfolio, industries can confidently implement PLCs into their automation systems, ensuring long-term reliability and scalability.

Conclusion

The programmable logic controller is more than just a control device; it is the foundation of modern automation. From industrial machinery and process plants to renewable energy and smart buildings, PLCs ensure efficient, reliable, and flexible operation. As industries embrace digital transformation and IoT-driven solutions, PLCs will remain at the center of innovation.

For businesses seeking reliable, high-quality PLCs, Enrgtech provides certified solutions that meet global standards, enabling smarter, safer, and more efficient automation systems.