Fluke Energy Monitor Clamp: What Makes It Essential?

In modern facilities, energy monitoring is no longer optional. A Fluke Energy Monitor Clamp gives technicians a practical way to measure current on live cables, understand real power usage, and maintain safe, efficient electrical systems across industrial and commercial sites.

Understanding the Fluke Energy Monitor Clamp

A Fluke Energy Monitor Clamp is a flexible or rigid current clamp designed to work with compatible energy loggers, analyzers, or multimeters. It senses the magnetic field around conductors and converts it into readable current values without disconnecting cables or opening live circuits.

This non intrusive approach is crucial in busy distribution boards, control panels, and switchgear. Technicians can clip the clamp around conductors, connectors, and busbars while the system remains online, which keeps production running and reduces downtime during inspections and power studies.

How the clamp works with sensors and electronics

Inside the clamp, precision sensors track the magnetic field surrounding the conductor. Signal conditioning electronics then translate this into a stable current signal that the instrument can read.

Because these signals feed directly into meters, controllers, and energy monitoring software, teams can capture trends and diagnose unbalanced loads before they cause failures in fuses, switches, LEDs, or sensitive electronics.

Key features for modern electrical systems

A Fluke Energy Monitor Clamp is built for demanding environments, so several design features make it suitable for day to day maintenance and advanced diagnostics.

Key characteristics typically include:

- Wide current ranges suitable for feeders, contactors, and final circuits

- Large jaw or flexible coil to wrap around multiple cables or busbars

- High accuracy across typical industrial temperature ranges

- Durable insulation and grips that support electrical safety practices

- Clear markings that help position the clamp correctly on conductors

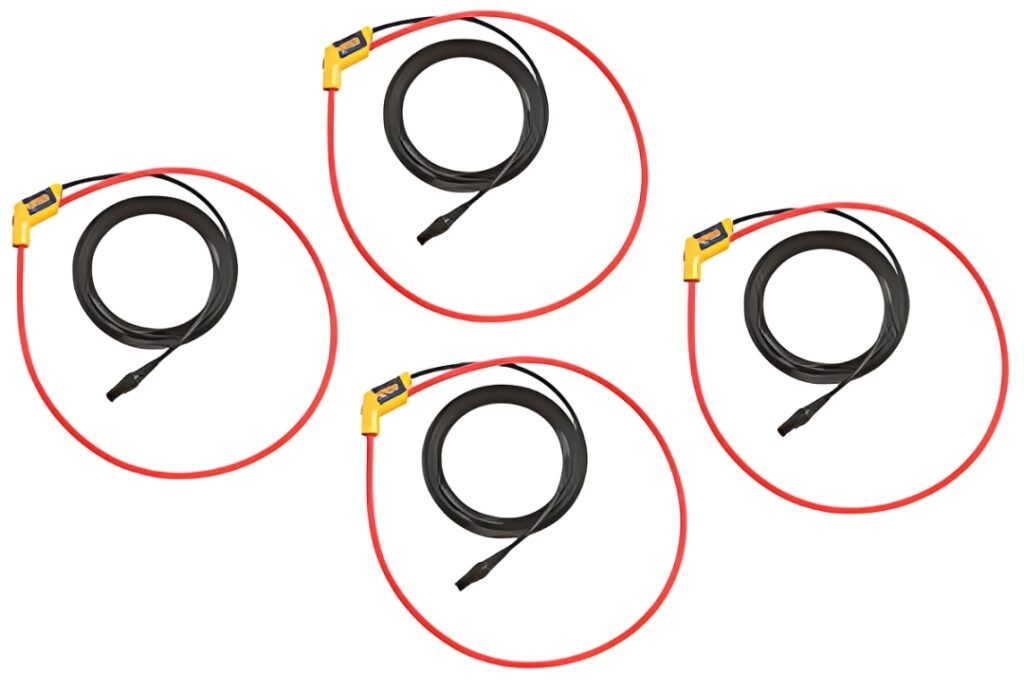

Some models use flexible coils that easily route around crowded panels, thermal pads, and tightly bundled cables. Others use rigid jaws for repeatable measurements in switchboards, control cabinets, and motor starters.

Integration with controllers and microelectronics

In many installations, the clamp connects to instruments powered by microcontrollers and microprocessors. These devices handle sampling, filtering, and data logging, then communicate with laptops or industrial controllers for further analysis.

This integration lets engineers correlate current profiles with process events, sensor readings, and thermal conditions. It also supports predictive maintenance programs by highlighting overloads, neutral currents, and harmonic patterns that could shorten asset life.

Where to use a Fluke Energy Monitor Clamp

Technicians can deploy a Fluke Energy Monitor Clamp anywhere current measurements are required without breaking the circuit.

Common applications include:

- Verifying feeder and branch circuit loading in distribution boards

- Checking current balance on three phase motors and contactors

- Measuring current on circuits feeding LEDs, controllers, and sensors

- Performing energy surveys on production lines, HVAC systems, and data rooms

- Troubleshooting nuisance trips, overheating cables, and abnormal voltage drops

In each case, the clamp helps identify which loads drive energy use, how equipment behaves under real operating conditions, and where safety margins may be at risk.

How to use a Fluke Energy Monitor Clamp safely

Even though the clamp provides a non contact method, safe working practices remain critical. Before applying the clamp, technicians should review the circuit layout, protective devices, and lockout procedures.

Useful safety habits include:

- Inspecting the clamp housing, insulation, and grips for damage

- Confirming CAT rating, current range, and instrument compatibility

- Wearing appropriate personal protective equipment for the environment

- Keeping hands behind safety guards during placement on live conductors

- Avoiding oily surfaces or conductive dust that could compromise insulation

Following these steps reduces risk while still allowing fast measurements on live systems, from small control panels to large switchboards.

Choosing the right Fluke Energy Monitor Clamp

Selecting the correct clamp for an energy monitoring task depends on system layout, conductor size, and the type of instrument in use.

Important factors to consider are:

- Maximum and minimum current to be measured on each circuit

- Conductor size, number of cables, and available access space

- Required accuracy for energy audits or compliance reports

- Frequency range if measuring drives, inverters, or nonlinear loads

- Connection leads and connectors needed to interface with instruments

When clamps work alongside thermal imagers and other tools, they can support detailed energy audits that highlight inefficient loads and guide upgrade decisions.

Practical tips to maximize clamp performance

To get consistent measurements, technicians should develop repeatable methods when installing a Fluke Energy Monitor Clamp. For example, always place the clamp at the same position on the conductor, with the arrow or reference mark pointing in the same direction.

Further practical tips include:

- Routing leads away from high energy cables to minimize noise pickup

- Checking zero adjustment before starting a new measurement session

- Recording circuit references clearly on laptops or field notes

- Comparing clamp readings with installed meters where available

- Using multiple clamps on multiphase systems for faster surveys

Good practices at the measurement stage produce cleaner data and more reliable insights for decision makers who rely on energy dashboards and reports.

How the clamp supports long term energy strategies

Beyond daily troubleshooting, a Fluke Energy Monitor Clamp plays an important role in long term energy management strategies. By providing accurate current data, it helps engineers calculate demand, identify peak loads, and evaluate how changes in process timing or equipment selection affect consumption.

When used with sensors that track temperature, flow, or other process variables, the clamp allows teams to link energy use directly to production output. This insight supports upgrades ranging from efficient LEDs and capacitor banks to advanced controllers and microcontrollers.

As organizations continue to connect more devices, from laptops to industrial controllers, clear visibility into energy use becomes vital. A Fluke Energy Monitor Clamp delivers that visibility, helping teams maintain safety, reduce waste, and support reliable operation across modern electrical networks that depend on advanced electronics, cables, contactors, capacitors, and related components.